Despite COVID-19, substantial volumes of lithium-ion (Li-ion) batteries will soon be reaching their end-of-life stage, raising concerns about disposal and recycling. These energy storage solutions are commonly found powering popular portable digital devices such as smartphones and laptops. The associated waste totals are at risk of risingly sharply over the next two decades, however, as result of the recent and ongoing boom in electric vehicle (EV) sales.

A new report from IDTechEx estimates that 2020 will see 330kt of Li-ion battery waste. The majority of this will derive from consumer electronics. However, it is the sheer volume of end-of-life EV batteries which will be problematic if not managed properly.

So, as an unintended consequence of our efforts to tackle climate risk by cutting carbon emissions from transport, could we be in danger of seeing our circular economy ambitions take a massive hit?

The good news, according to the research findings, is that there are several factors which suggest the recycling market will grow to meet the surge in demand.

Minimise supply chain risk

The large electric vehicle markets of Europe and the USA are increasingly concerned with the implications of relying on external raw material and battery supplies and are actively seeking to develop a domestic supply of critical materials, including those present in Li-ion batteries. While the US is home to some key material resources such as graphite and lithium, Europe is resource-poor. Recycling, of manufacturing scrap or end-of-life batteries, could therefore be a key resource allowing for some diversification of supply.

Capture embedded value

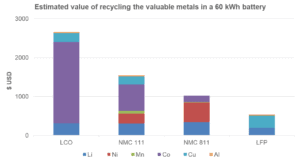

For the lithium-cobalt-oxide batteries used in the vast majority of consumer devices, the intrinsic value is relatively high, and recycling can be profitable from recovering cobalt and copper alone. Indeed, old consumer electronics could be a significant source of cobalt in the short-medium term, though hoarding, collection and distribution challenges make this unlikely.

EV batteries on the other hand will be easier to track, collect and manage. However, the material value in an EV battery, on a $/kg basis, is lower due to the smaller amounts of cobalt used per kWh — and manufacturers are aiming to continue reducing cobalt content, and even nickel, too, further down the line.

With this in mind, numerous companies are developing and commercialising various recycling processes, and combinations thereof, to recover more material from Li-ion cells in order to capture as much value as possible.

Improve the sustainability of Li-ion batteries

The importance of sustainable battery production should not be overlooked. The growth in electric vehicle and stationary storage markets are driven by environmental concerns. As the environmental and ethical impacts of Li-ion production are increasingly highlighted, so too is the importance of considering the entire life cycle of Li-ion batteries.

Ensuring proper end-of-life management, for example via recycling, and using recycled material can help reduce energy and material requirements throughout the manufacturing chain and could help present companies with a marketing advantage.

Europe has seen increasing interest in providing EVs with domestic supply of batteries, for instance from Northvolt, PSA-Saft, TerraE or Britishvolt. However, competing with Asian battery giants on volume and cost is likely to be a difficult proposition. Instead, ensuring minimal environmental footprint and visible supply chains can be a differentiator for them.

The IDTechEx report Li-ion Battery Recycling: 2020-2040 provides an overview of the current market landscape and trends in Li-ion battery recycling, as well as an in-depth analysis of key recycling processes and technologies. It also looks at key market players and explores the battery recycling value chain from a lifecycle perspective: from mining and processing, to battery materials and production, battery usage, throughout to recycling (or second life and recycling).

Further Reading:

- Information about the report Li-ion Battery Recycling: 2020-2040;

- More about IDTechEx Research and Consultancy, in general.

>>> Do you have sustainability news to broadcast and share? If you would like to see it featured here on SustMeme, please use these Contact details to get in touch and send us your Press Release for editorial consideration. Thanks.