Reusing fibres from worn-out garments to make new ones, a leading workwear manufacturer is pioneering a method of circular production that not only reduces waste, but also the need for virgin material.

Coming onto the market this spring, the first circular product from Swedish workwear specialists Fristads is a sweatshirt made from 15% closed-loop fibres created from collected used own-brand garments.

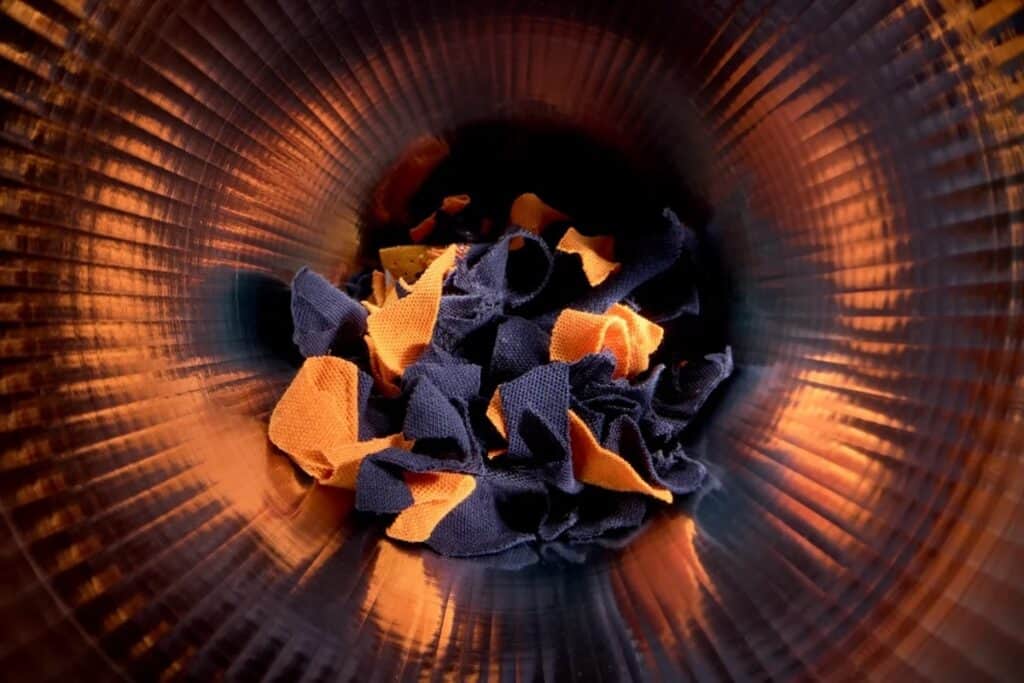

To make the new fabric, the collected Fristads material has been shredded into smaller pieces and turned into fibres. The closed-loop fibres are then mixed with other fibres to make yarn.

First step to change the ending

The circular manufacturing process addresses both end-of-life disposal and recycled content goals.

It is a win-win for sustainability, says Anne Nilsson, Director of Marketing and Sustainability at Fristads:

“We have been working on reducing the environmental impact of our production for years, but we also recognise the need for innovative closed-loop solutions after the garment is worn out.”

This more circular garment will have an Environmental Product Declaration (EPD), disclosing exactly how much the impact of manufacturing will be reduced by using existing fibres to make new ones.

The launch of the first circular product is a result of almost three years of hard work, trying to find the optimal solution on how to secure the different flows in the process, as well as ensuring quality control.

The sweatshirt is an important first step, explains Lisa Rosengren, Head of R&D Raw Material at Fristads:

“The share of circular fibres in the final product has been carefully chosen to safeguard our high quality. Our goal is to increase the amount of closed-loop fibres over time, as we continue to develop our circular solution.”

How the loop is closed and what that means

The terms open loop and closed loop are commonly used to describe two different types of recycling flows.

In an open-loop flow, textiles are collected and processed into other products, for example filling for car interiors, or construction materials or insulation.

In a closed-loop flow, the textiles are processed into new fibres that are mixed in with other materials and used to produce new clothes, creating a circular production process.

Step by step, this is how the process of closing the loop looks for the Fristads sweatshirt:

- Collecting — worn-out Fristads garments are collected from customers and sorted at a recycling centre;

- Preparation — the material is prepared by being shredded into smaller pieces and turned into fibres;

- Making the yarn — the fibres are mixed with other fibres to make yarn, with 15% closed-loop content;

- Creating new material — the yarn is used to make new fabric; and

- Making the final product — the fabric is turned into new products, partially made from used workwear.

Certified recycling as traceability guarantee

Fristads has been driving the development of durable and functional workwear since 1925. Its selection of clothing includes classic as well as contemporary garments, produced for a wide range of industries.

The company’s circular product development first began in 2021 when a polo shirt was made partially from discarded garments from one its customers in the Netherlands.

Via a joint pilot programme, worn-out polo shirts were collected and recycled into new garments, effectively closing the loop on some of Fristads’ clothing production.

The recycling process for the project was certified in 2022, making Fristads the first clothing producer in the region able to guarantee the traceability of recycled closed-loop raw materials for a specific customer.

The Dutch model serves as a blueprint for Fristads implementing and scaling up recycling in all its markets.

As a business, Fristads forms part of the global Hultafors Group. Owned by Investment AB Latour, Hulfators Group offers a broad portfolio of products and brands catering to professional craftspeople.

Further Reading:

- More about Fristads; the global Hultafors Group; and owners by Investment AB Latour;

- More about the new circular sweatshirt product, in particular;

- Also on SustMeme, VCs back vegan biomaterials in luxury textiles;

- Also on SustMeme, Innovative leather alternative made from beer waste;

- Also on SustMeme, Traceability boost for cotton in fashion and textiles;

- Also on SustMeme, Wood-based water tech removes 80% dye pollutants;

- Also on SustMeme, Plastic waste gets Recycled for Radness into eco snow gear;

- Also on SustMeme, Fashion waste landfill piled high as the moon;

- Also on SustMeme, Sustainability: ‘Fashion Economy’ in ‘The Times’.

Check out the full archive of stories on the SustMeme Circular Economy Channel, Sponsored by Dow.