In a breakthrough for battery cell chemistry and automotive supply chains, a next-generation material has successfully been produced which could increase electric vehicle (EV) range by up to 20%.

The Lithium Manganese Iron Phosphate (LMFP) cathode active material has been developed and validated by UK-based battery solutions and nano technology pioneers Integrals Power Limited (IPL).

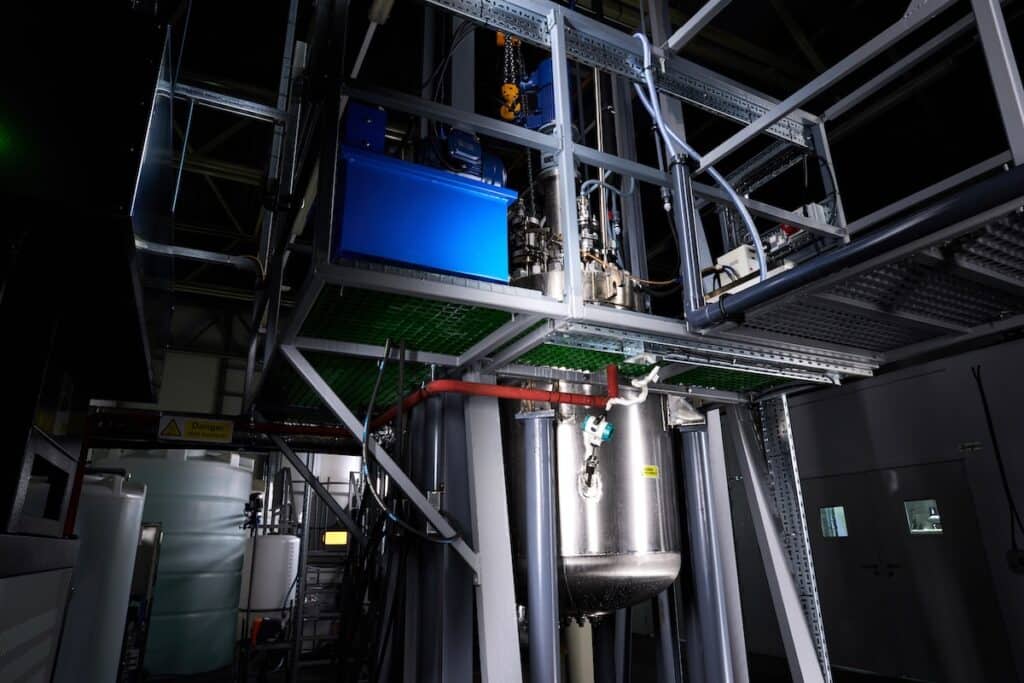

The LMFP materials were produced at the IPL facility at Milton Keynes, demonstrating that the technology can successfully be scaled to series production volumes in future. This marks a milestone in the development of a high-performance, sustainable domestic supply chain for the UK battery industry.

Cells made from Integral’s LMFP material have been tested and assessed by the Graphene Engineering Innovation Centre (GEIC), part of Graphene@Manchester at The University of Manchester, England.

Beating trade-off to boost voltage and cut cost

The Integrals Power technology delivers an LMFP material featuring a high manganese content to increase voltage while offering a similar specific capacity to the best Lithium Iron Phosphate (LFP) materials.

Applying its propriety materials technology and patented manufacturing process, the company has managed to avoid the drop in specific capacity that typically occurs as the percentage of manganese is increased. The result is cathode active materials which support higher voltages and high energy density.

Overcoming this trade-off, these cathode active materials combine the best attributes of LFP chemistries — relatively low cost, long lifecycle, and good low-temperature performance — with energy density that is on a level comparable to that seen in more expensive Nickel Manganese Cobalt (NMC) chemistries.

The solution is a breakthrough in battery tech, says Integrals Power Founder and CEO, Behnam Hormozi:

“The challenge that the automotive industry has been trying to overcome for some time is to push up the percentage of manganese in LMFP cells to a high level while retaining the same specific capacity as LFP.

“Our proprietary materials and patented production processes have enabled us to overcome this trade-off and increase manganese content to 80%, placing us at the cutting edge of LMFP chemistry.

“With third-party evaluation from the GEIC, we’re proud to have developed a world-class cell material in the UK that can rival the performance of NMC but is more sustainable and more affordable.”

The good news for the transition to e-mobility across the wider automotive sector is that this performance boost means EV range could increase by up to 20%, or battery packs become smaller and lighter.

Supply-chain security, traceability and transparency

The LMFP materials feature 80% manganese, instead of the 50-70% typically found in competing materials, and have higher specific capacity: 150mAh/g, while delivering a voltage of 4.1v (versus 3.45v for LFP).

Third-party testing by experts at the GEIC have been completed on coin cells and now evaluated using EV-representative pouch cells. The developed materials will soon be available for cell suppliers, battery manufacturers, and OEMs to evaluate and benchmark.

Collaborations that bridge the gap between academia and industry are vital to push next-generation technologies towards commercialisation, says GEIC’s Applications Manager in Energy, Nicky Savjani:

“Our GEIC Energy facility, combined with its dedicated team of battery engineers, is decarbonising the transport sector and reinforcing the UK’s leadership in developing sustainable battery technologies.

“The battery cells we produced using Integral Power’s LMFP materials exhibited competitive specific capacity during testing, highlighting their potential to enhance EV efficiency and reduce costs by increasing range.“

Integrals Power produced the high-performance LMFP cathode active materials at its new UK facility, alongside its proprietary LFP chemistry. The capability to manufacture materials such as these in the UK is critical to the development of a sustainable domestic battery industry and supporting not just the 2035 ban on sales of new combustion engine vehicles but also 2050 net zero emissions targets.

Establishing manufacturing in the UK will also enhance supply chain security and transparency, and mitigate geopolitical issues such as import tariffs on EVs and their components. Integrals Power sources all its raw materials from European and North American suppliers for purity and high performance.

Accelerate commercialisation and scale-up of innovation

Integrals Power Limited (IPL) is a next-generation battery material company. Based in the UK, it is committed to the research, development and commercialisation of proprietary, high-performance, cost effective and scalable battery cathode active materials including LFP and LMFP.

IPL works closely with academic, research, and industrial partners in collaborative government-funded projects to accelerate the commercialisation and scale-up of these novel materials.

The company’s mission is to help enable the widespread adoption of e-mobility worldwide, contributing to reductions in CO2 emissions, improvements in air quality, and achieving net-zero.

Part of Graphene@Manchester at The University of Manchester, the Graphene Engineering Innovation Centre (GEIC) is truly unique in UK academia. It is a state-of-the-art translation centre, which accelerates lab-to-market development, enabling companies to fast-track Technology Readiness Levels.

This cutting-edge centre supports industry pioneers in their bid to launch new technologies, products and processes that exploit the truly remarkable properties of graphene and 2D materials.

In 10 years, GEIC has helped no fewer than 500 companies, from large corporations to spin-outs.

Further Reading:

- More about next-generation battery material company Integrals Power;

- More about the Graphene Engineering Innovation Centre (GEIC); and Graphene@Manchester;

- Also on SustMeme, Human rights risks in world battery supply chain;

- Also on SustMeme, EnTech superhub to turbocharge green revolution;

- Also on SustMeme, Fire risk call for regulation of e-bike batteries;

- Also on SustMeme, Net zero road transport is still possible by 2050;

- Also on SustMeme, All-electric lithium to power North America EV drive;

- Also on SustMeme, Electric SUV to boost market for battery swapping;

- Also on SustMeme, Second-life battery solution for circular EV charging;

- Also on SustMeme, As EV waste looms, is Li-ion battery recycling ready to roar?

- Also on SustMeme, Guest Blog: Are crumpled graphene balls the future for EVs?

Check out the full archive of stories on the SustMeme Transport & Mobility Channel, now available to Sponsor.